Fascination About Mobile Sandblasting Near Me

See This Report on Grit Blasting

Table of ContentsIndicators on Dustless Blasting Near Me You Need To Know6 Easy Facts About Sand Blasting Sand Shown8 Easy Facts About Abrasive Blasting DescribedFascination About Sand Blasting SandSandblaster For Sale Can Be Fun For Everyone

In all instances their usage can provide significant risk to drivers, such as burns due to projections (with skin or eye sores), drops as a result of strolling on rounded shot spread on the ground, exposure to dangerous dusts, warmth exhaustion, production of an explosive environment, and also exposure to extreme sound.Blasting lead-based paint can fill the air with lead bits which can be damaging to the nerve system. In the United States the Occupational Safety and Health Administration (OSHA) mandates engineered services to potential threats, however silica sand continues to be enabled although many typically used blast safety helmets are not adequately effective at protecting the blast driver if ambient degrees of dust exceed allowed limits.

Worn-look pants [modify] Many customers want to pay added for denims that have the appearance of being utilized. To offer the fabrics the right worn look sandblasting is used. Sandblasting has the risk of causing silicosis to the workers, and also in Turkey, greater than 5,000 workers in the fabric sector struggle with silicosis, and also 46 people are understood to have passed away from it.

Sandblaster For Sale Can Be Fun For Anyone

's Fair Profession Center performed a survey among 17 fabric companies that revealed really few were mindful of the dangers triggered by manually sandblasting pants. In 2013, study claimed that in China some manufacturing facilities generating worn-look jeans are entailed in different non-compliance with wellness and also safety and security policies.

How can you maximize your production operations with abrasive blowing up tools? What kinds of abrasives, shot as well as blast media are utilized? Can I dispose of, reuse, and also reuse used abrasives, shot, and also blast media?

The Greatest Guide To Sandblaster For Sale

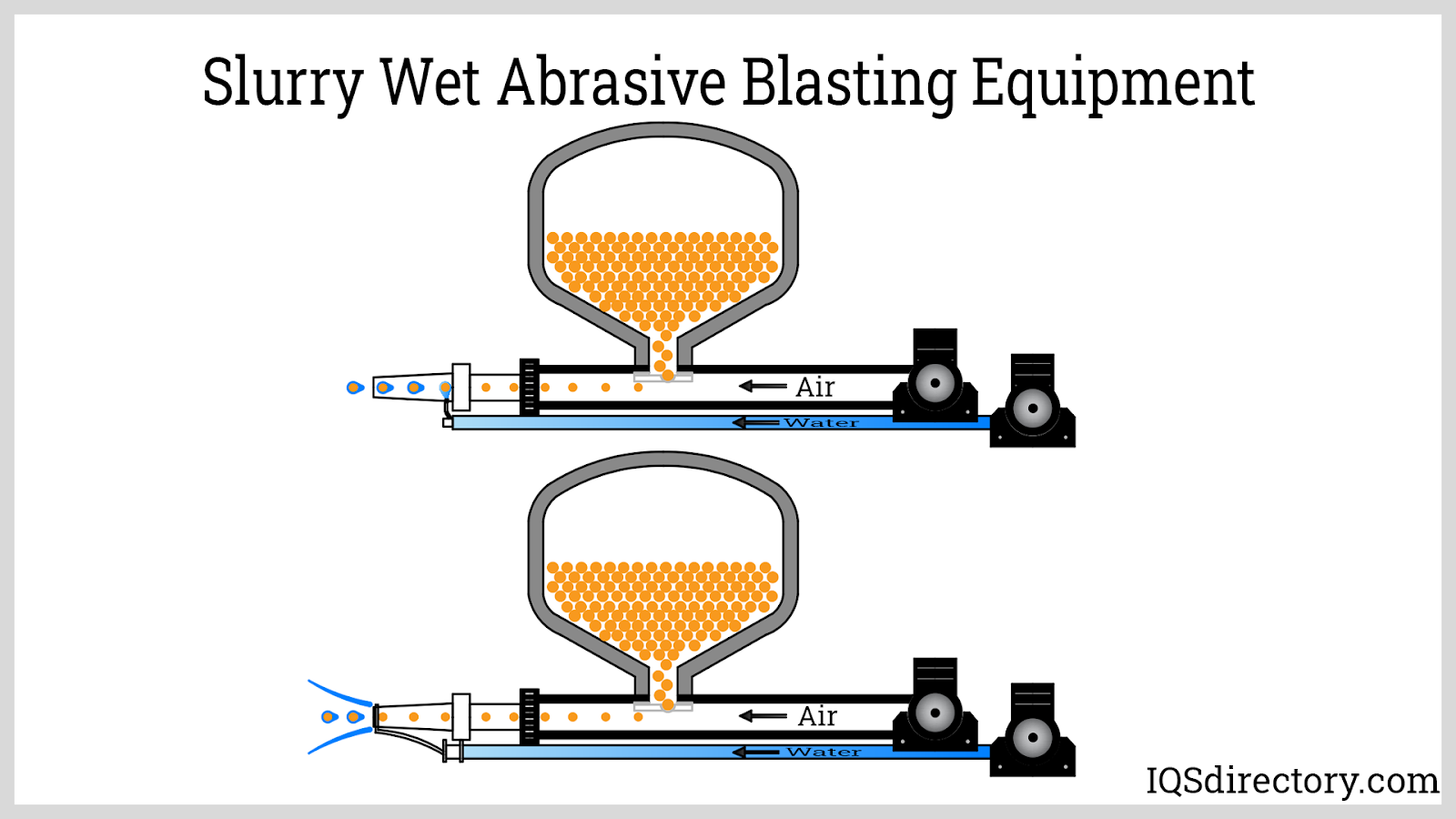

Detergents can be contributed to the water to loosen deposits, dissolve oils or greases and also speed up the cleaning procedure. abrasive blasting. Rust preventing representatives can be included in the water to avoid rusting of damp steel after the blowing up procedure is complete. If rust suppressors are not contributed to the water, then the steel should be dried, oiled, or painted after blasting to stop corrosion formation.

The water ring or halo nozzles give much less dust control than the water induction or shot nozzles. Slurry blast tools is tiresome for operators to bring and also deal with due to the fact that a hefty water hose is attached.

Vapor abrasive blast systems provide the highest level of dirt suppression, up to 95%. The abrasive slurry takes a trip with a blast pipe to the slurry blowing up nozzle.

Sand Blasting Sand Fundamentals Explained

Ice blowing up cupboards should be designed to handle the chillier media, in addition to the condensation on lines, cabinet wall surfaces, pots, and also vessels. The products of building can not include kinds of plastics or steels, which end up being brittle at reduced temperature levels. Dry ice is gentler and also softer than plastic media. Dry ice media can be in 2 kinds: pellet and also cut or useful content snow-like flakes.

Preferably, the media and also dust created from blowing up parts is consisted of within the cabinet and also purification system. Blast cabinets establish leaks as seals wear as well as tear over time.

Fastening allows the components to be a lot more get more conveniently eliminated for cleansing, repair, and substitute. Bonded blast closets tend to be a lot more impermeable with less leakage of blast media and dust into the shop, but replacement of used closet sides or bottoms is difficult. The abrasive blast stream wears all-time low and sides of the cabinet over time.

The Facts About Grit Blasting Revealed

What Are Blast Cupboard Products of Building? In certain dry blasting applications such as medical instruments as well as clinical implants, stainless steel building products might be used to stay clear of iron contamination of a surface area.

Steel components or steel shot impacting stainless steel components can move metal to the stainless surface area, which can modify passivation and lead to rust on the surface area. Wear-resistant steel linings are tactically placed within blast chambers to minimize wear of the blast device (shot blasting near me). Wear-resistant alloys include manganese steels such as Manganal and nickel and also chromium white actors irons such as Ni-Hard alloys.